IT data center room in room

are complete room constructions and protect the hardware inside against all physical damage. Thus they offer comprehensive protection against:

- fire

- fire water

- fire smoke gases

- water damage

- building moisture

- dust

- debris loads

- electromagnetic interference

- theft

- sabotage

- overheating

- system failure

We integrate the size and equipment you need into an existing building.

The room-in-room cell is also suitable as a solution in old buildings.

The room-in-room solutions

- offer the possibility to be equipped with extensive accessories such as air conditioning, fire detection, extinguishing gas systems, UPS systems, access control and much more.

- can be delivered from 9m² up to any size (size and equipment result from the number of

server racks) - are modular, fire-resistant, flue gas-tight, fire-fighting water-tight, sound-absorbing and

debris-absorbing safety rooms - are individually installed in an existing building according to customer requirements

Our design team builds the room including all safety components, whose parameters are finely tuned

to each other. The room is handed over to you ready for use, including training and documentation.

We provide an unrivaled long-term guarantee with a maintenance agreement for the implemented overall solution.

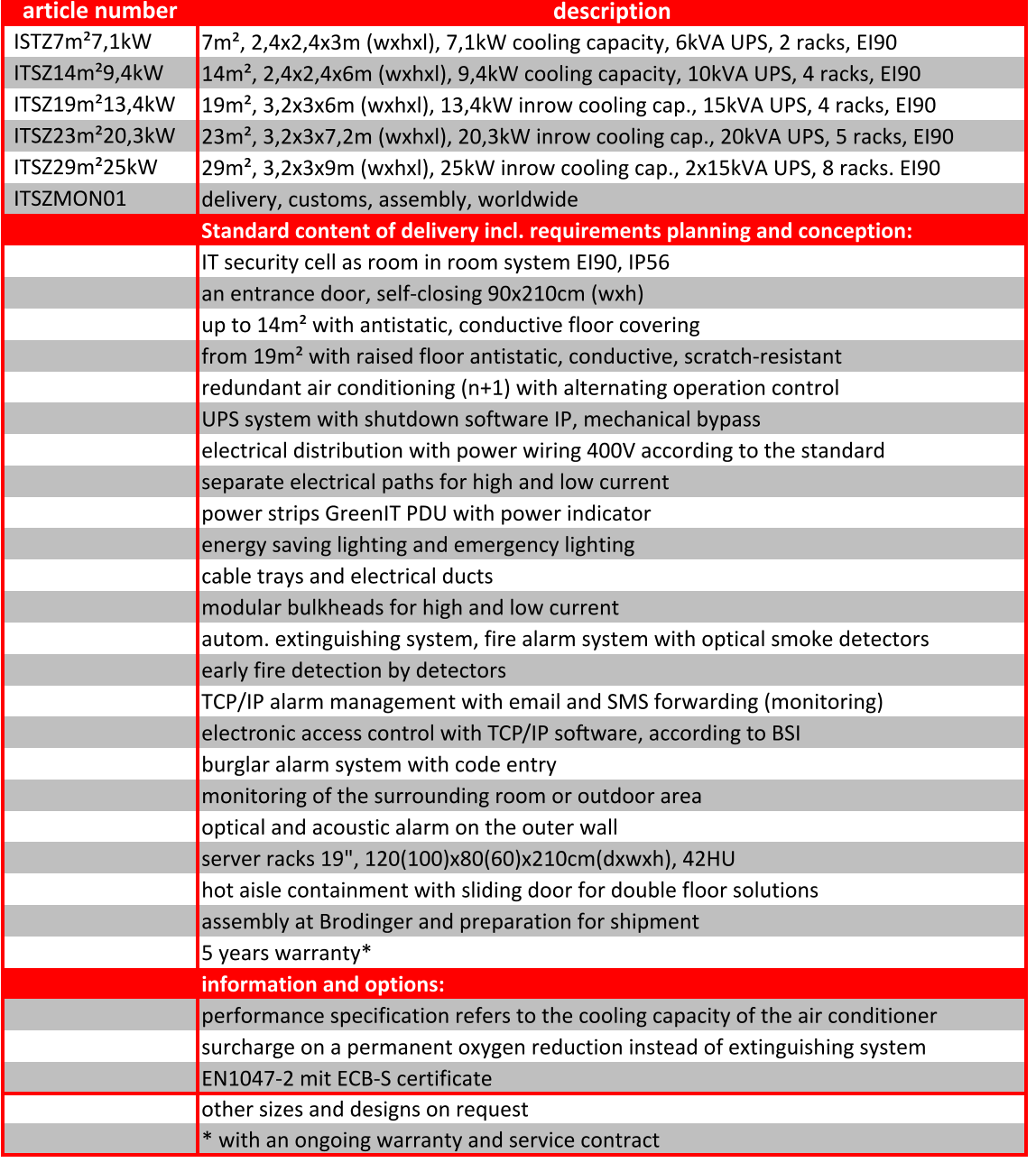

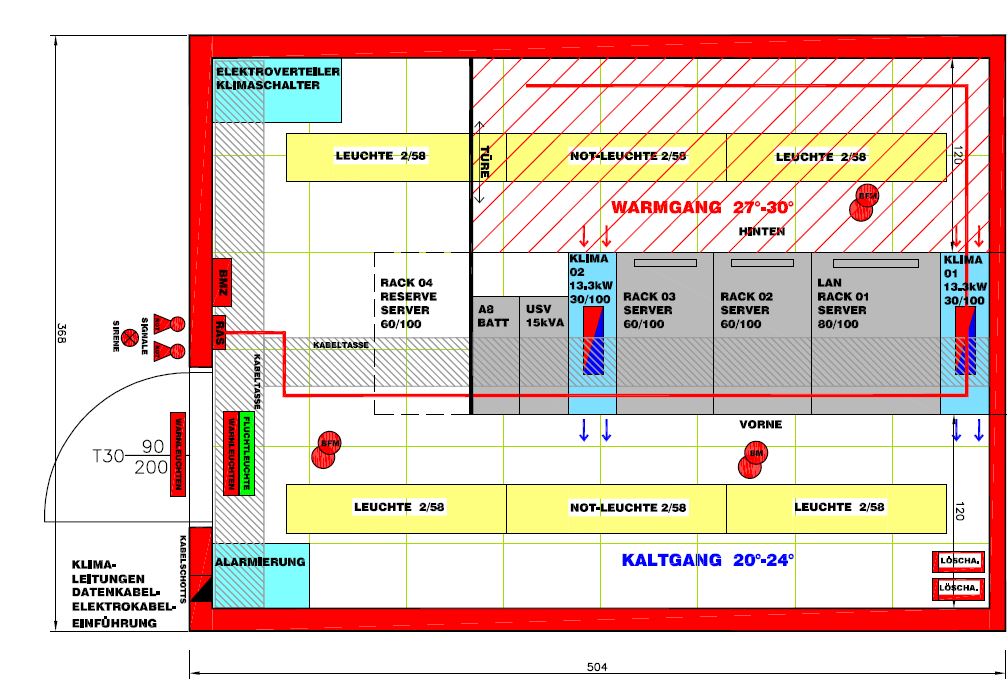

Server room: samples of different types

More versions can be adapted according to

customer requirements.

Here you can get further information.

* Manufacturer warranty can be extended to 5 years

Room in room construction

Installation example of a room in room system with increased fire load (IT security cell) in a new company building.

In order to build a server room according to the state of the art, we deliver the planning under the following considerations:

- own EI90/F90 fire compartment with smoke gas density (floor, wall, ceiling)

- sound insulation of the floor, walls and ceiling at least 33dB

- U(K)value 0.31 W/m²K of the floor, walls and ceiling

- fire water-tight room construction IP56 from all sides

- N50 value maximum 0.5 when using fire prevention by oxygen reduction

- EI90 fire protection door with a DIN 18095-1 smoke protection 4-sided circumferential frame, opening in escape direction, self-closing, optionally with electric security lock, panic fittings, min. 850mm wide, standard height

- S90 cable bulkheads

- K90 fire dampers with electric servomotor, normally closed in all supply and exhaust air openings

- antistatic, conductive double floor or floor covering

- electric supply line

- footprint for two air-conditioning outer parts

- condensate water connection near the server room, maximum 5m away

- dust-free room construction

- load capacity according to the specifications of the server room equipment supplier

Room in room planning

We plan your room in room system according to the following standards and certifications:

- general building authority approval for all parts according to DIN4102 F90/F120/F180.

- temperature increase in fire far within EN 1047 part 2.

- water leakage rate 0 with vertically and diagonally falling water as well as with spray and splash water

- fire water proof IP54

- smoke protection according to DIN 18095-1

- protection against debris loads up to 300kg/m² with an IT cell DIN EN 14195

- burglary protection WK2 to WK6 according to DINENV1627:1999

- air permeability according to EN 12207 class 4

- electrical engineering ÖVE TAEV, EN 12646-1

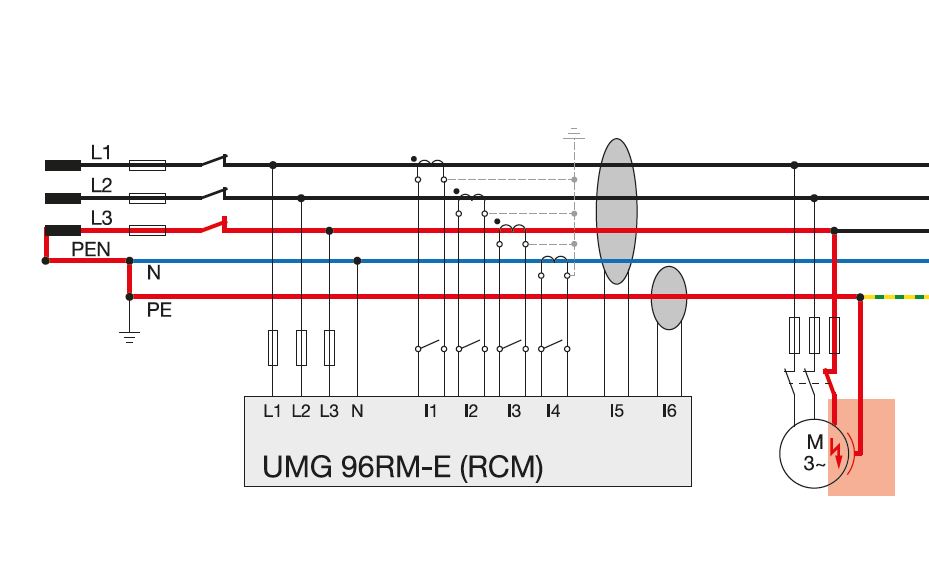

Differential current monitoring

as important equipment accessories.

Residual current monitoring devices (also called residual

current monitors) are used to monitor earthed networks

(TN and TT systems) for residual currents or differential currents.

The sum of the currents of all conductors except the protective

conductor is measured by means of measuring current

transformers.

As a rule, residual current monitors (abbreviation RCM,

Residual Current Monitor) are used to provide the user with a

message before the shutdown threshold of an RCD is reached.

Residual current monitoring devices detect deterioration of the

insulation level early and reliably.